Our New Year’s Resolution

January…it’s the time of year for new beginnings and new ideas. New pledges. Resolution. Sometimes bold or even wild imaginings. You don’t stay in business for more than 40 years without taking some risks.

Here at Giftsin24.com, the retail website of Embossed Graphics, we emphasize precision and quality above all else. But we also stand for…

- Optimism.

- Passion.

- Effort.

- Will power.

- Grit.

- Determination.

- Resolve.

We are proud of our products and the effort we put into them. Our New Year’s resolution is to continue our pursuit of excellence in all we do.

Which got us thinking…do you know how we do what we do?

The world of printing is fascinating. There’s a lot going on in our production facility. Here are a few of the processes behind the products you buy from us.

How We Do What We Do

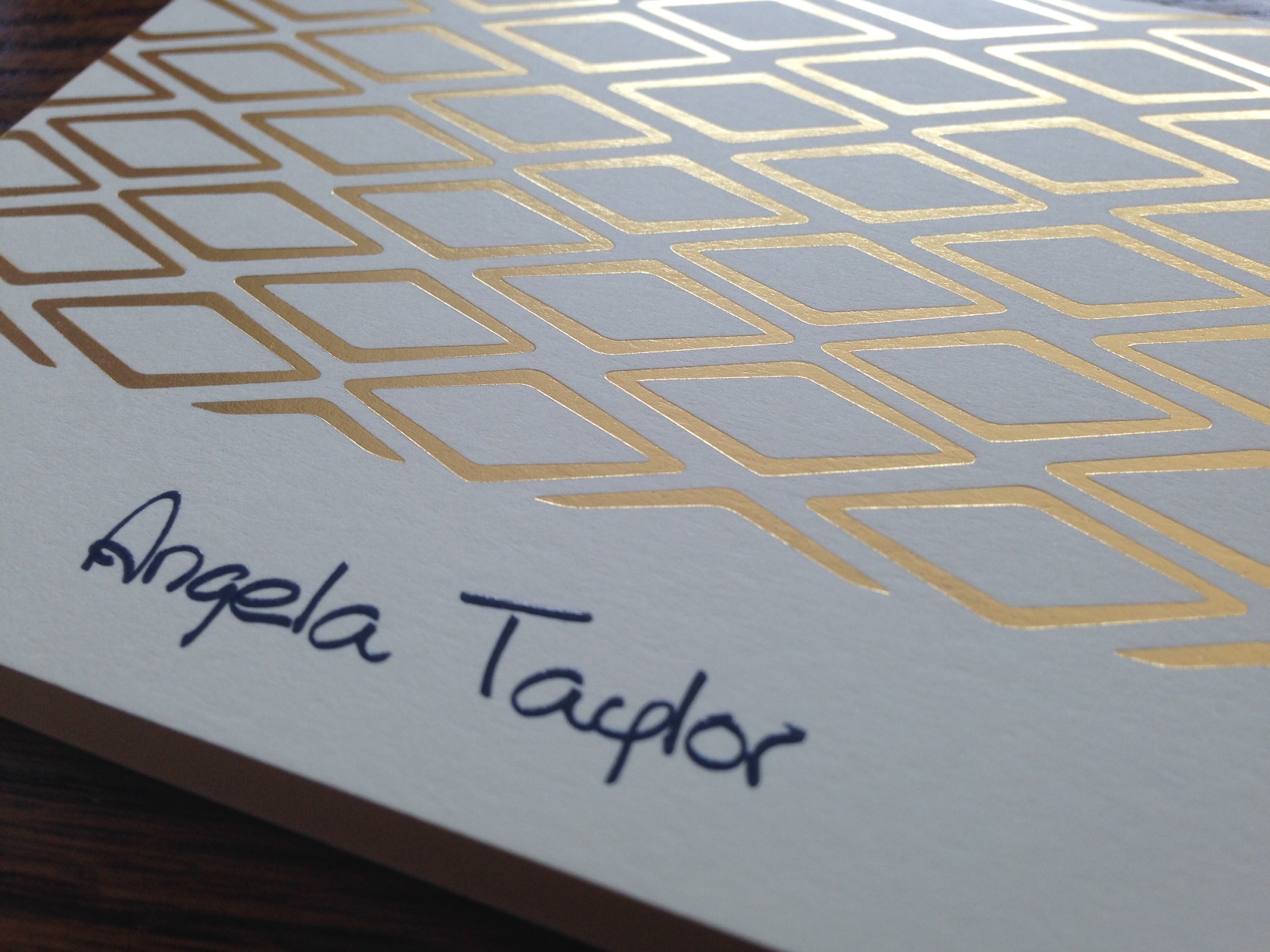

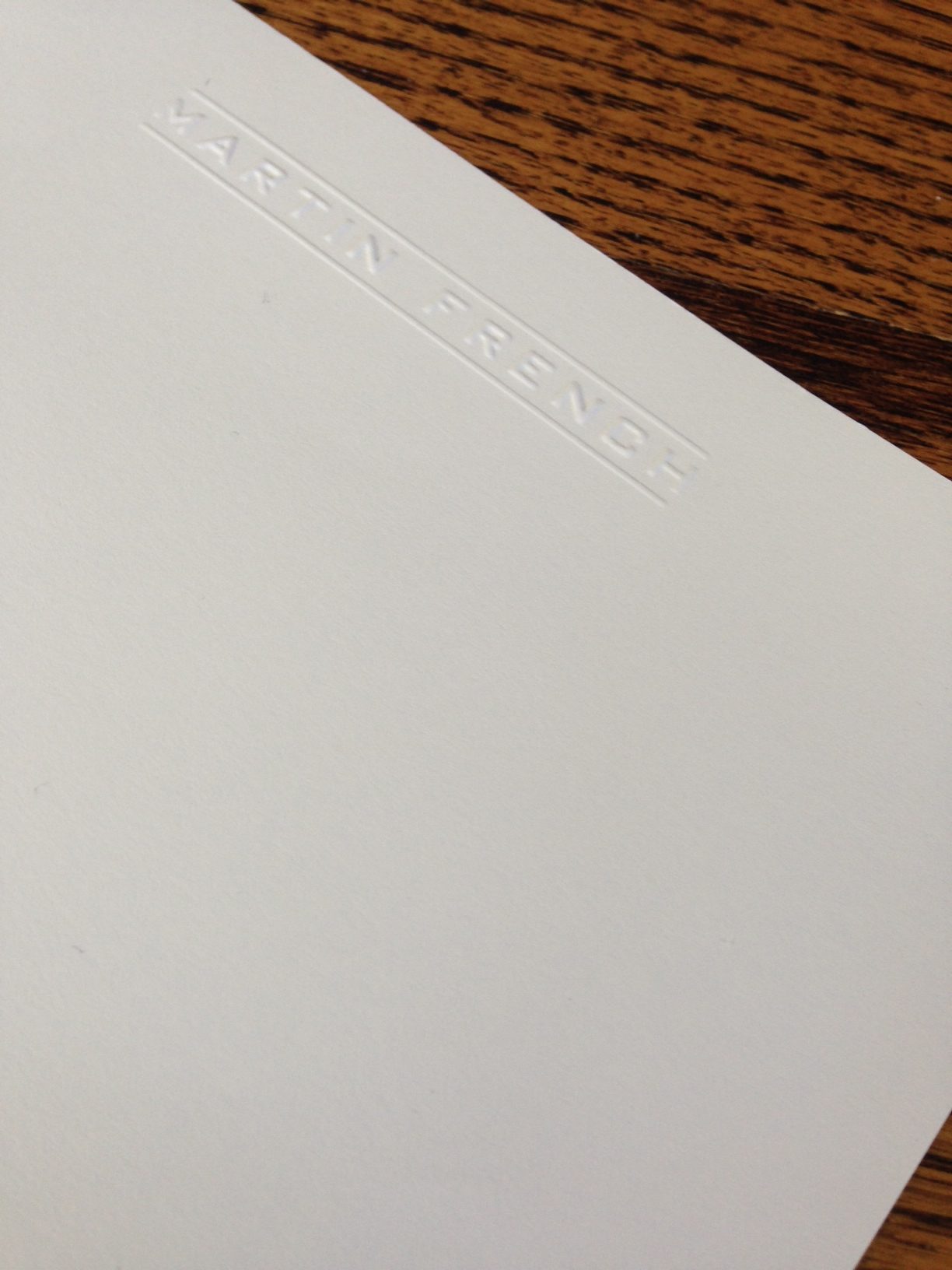

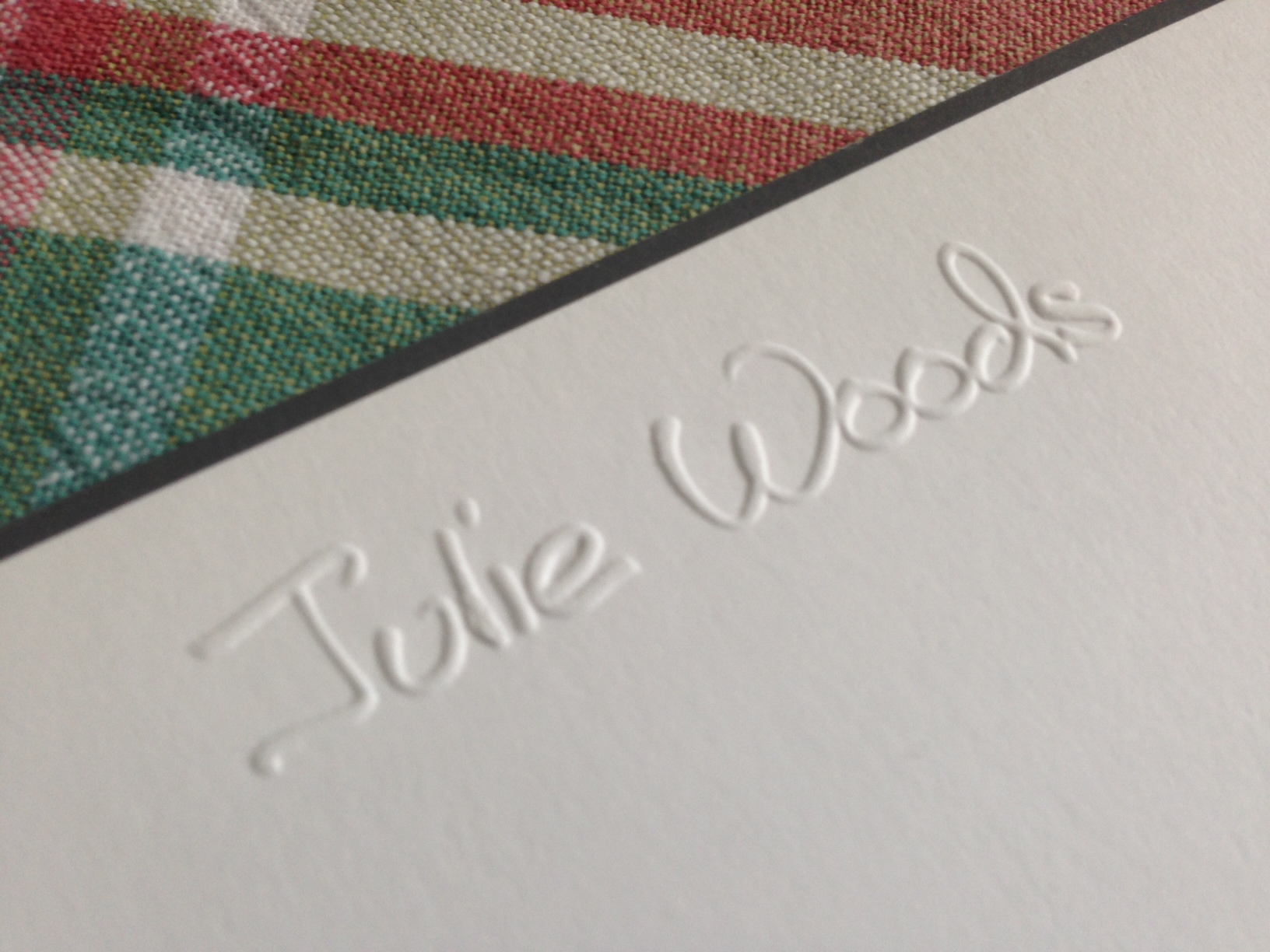

Embossing – Our embossed stationery features elegant, textured images. We achieve these through a traditional, centuries-old process known as embossing, where we press a die (a block with a reverse image of your monogram) into paper. While we employ no ink in this process, nevertheless, our embossed monograms and lettering styles convey meaning: tradition, quality, energy and style.

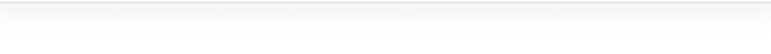

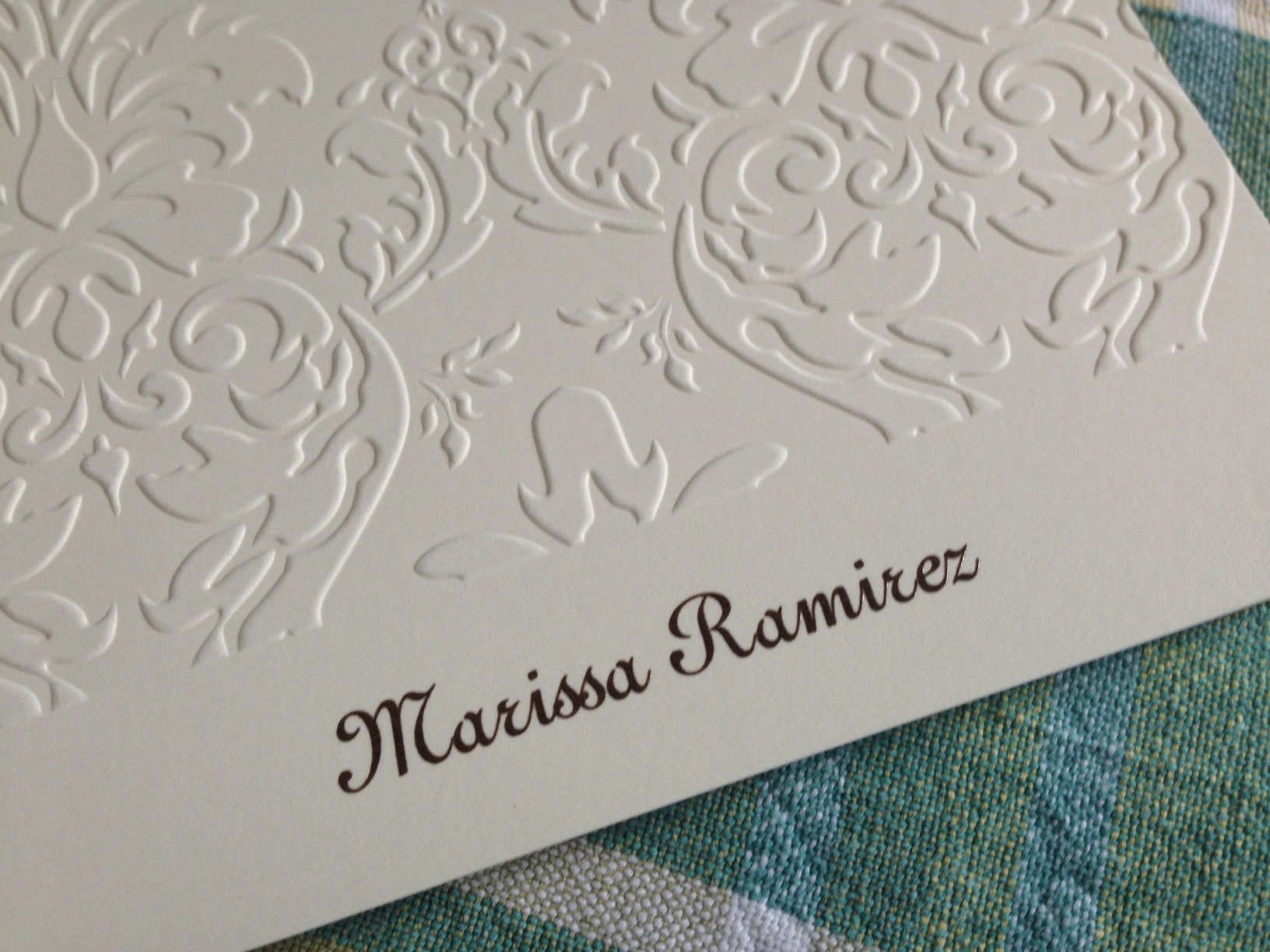

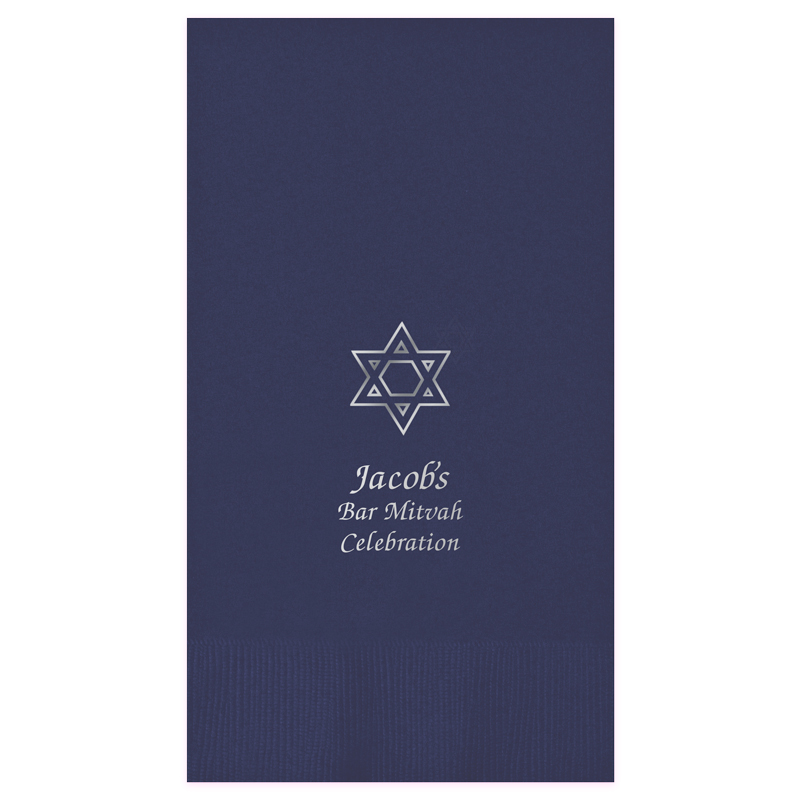

Foil Pressing – Our foil-pressed napkins and stationery embellishments offer just the right amount of color plus shimmer to make your personalization stand out. To create foil-pressed products, we use a heated die to adhere a thin sheet of foil to the paper. The result can range from soft and elegant silver or opal … to vivid blue or red … to bold gold or black.

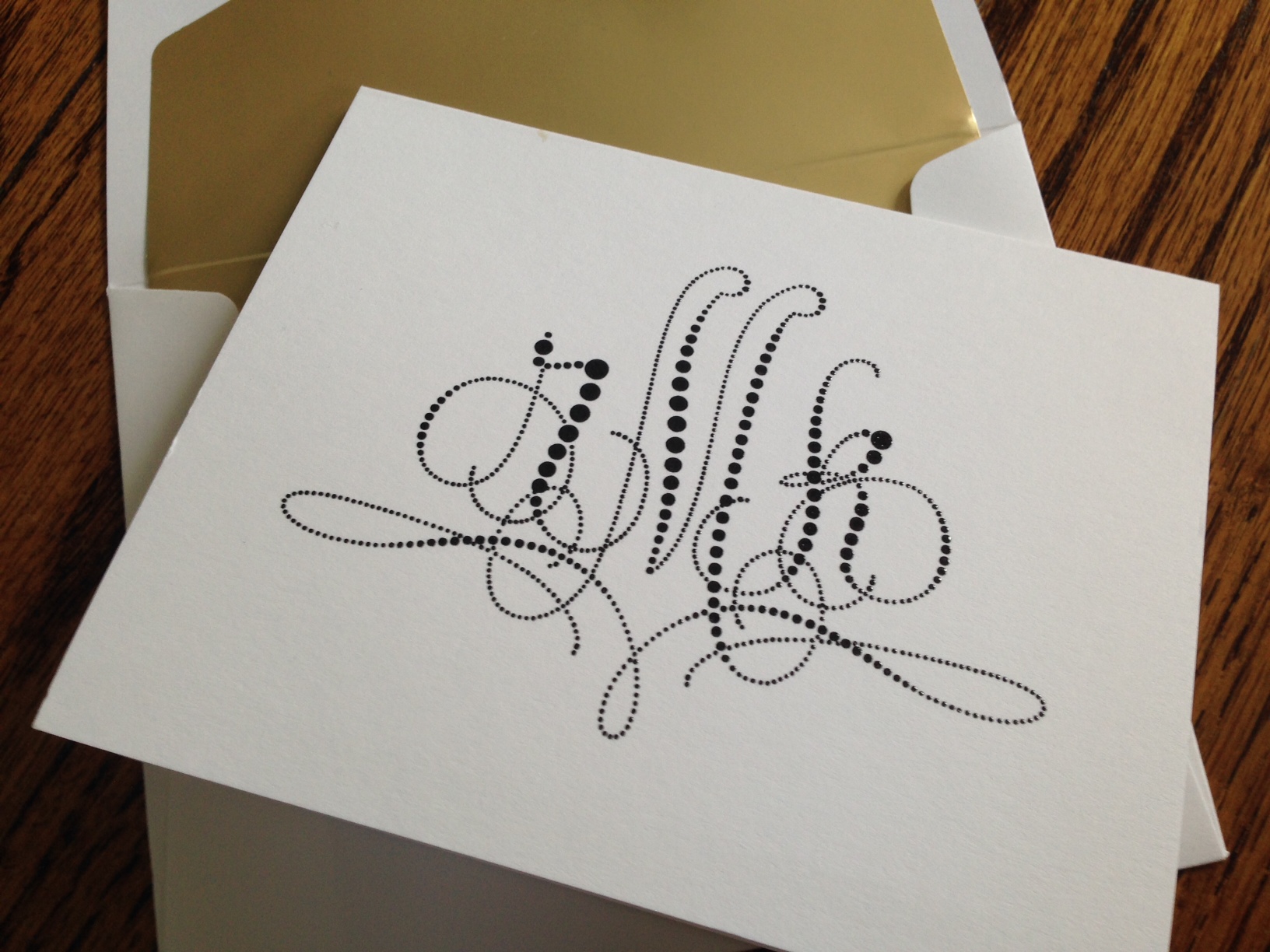

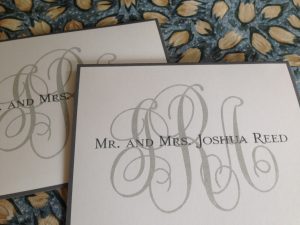

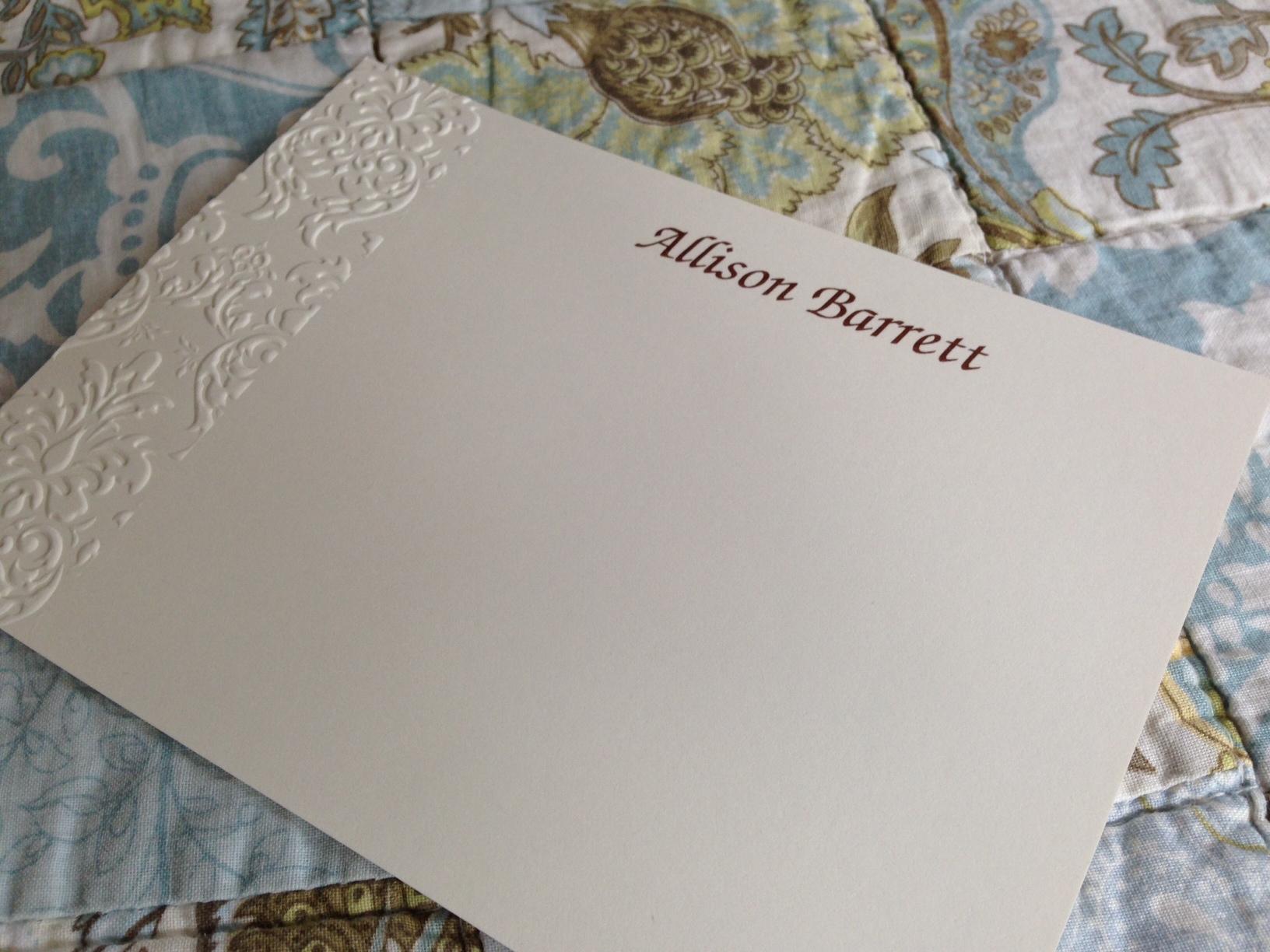

Thermography – It’s a big name that means “raised ink.” We use this process on our stationery. First, we print an image on paper. While the ink is wet, we dust it with a powder and apply heat. The heat fuses the ink and powder together and makes it raise above the paper surface. The result is a delightful, shiny image filled with texture and color.

Laser Engraving – We use a laser to personalize our engraved gifts, such as wine glasses, bamboo cutting boards and cork coasters. It’s flashy and fun and high-tech. We use a laser beam to etch into wood, glass, cork or other material. The laser creates such high heat that it vaporizes the material. It takes just a pulse with the laser, so we work very quickly and precisely.